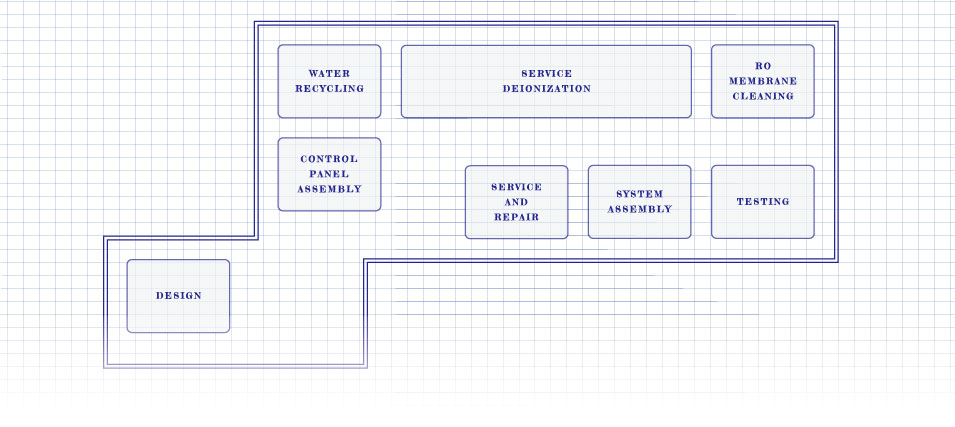

All Water Systems, Inc. ensures every product that comes from our state-of-the-art facility and every service we provide meets the same great standard that our company is known for. Our facility includes designated areas for every aspect of water treatment from the initial designing process to system assembly and testing.

Not one, not two, but three state-of-the-art regeneration plants are located in our facility. Multiple plants provide the ability to regenerate hundreds of cubic feet of resin per day resulting in faster response and fresher tanks. Go To Page

Our dedicated membrane cleaning area consists of our 4” and 8” cleaning stations as well as our pre-test and post-test stations. Operators are able to tailor cleanings by utilizing proprietary cleaning chemicals with specific surfactants and additives to provide optimum cleaning results. Our operators enter pre and post test results in our membrane software program where they are recorded and normalized for the customer. Go To Page

Over time, every system will require maintenance. Most service calls are handled at the customer’s facility by our experienced staff of service technicians in our fleet of fully stocked service vehicles. On occasion, some equipment will need to be serviced at our facility. Our flex space service and repair department provides the space to repair anything from a small control valve to a 100 GPM Reverse Osmosis System. A large inventory of parts will keep your service on track and on time. Go To Page

Projects come to life in our design center where systems are moved from idea to implementation plans and schematics. Each project benefits with input from multiple sources to ensure the right equipment is chosen for the application. While optimum performance from a complete package is always the goal, special consideration is given for serviceability and even future growth. No details are left to chance. Go To Page

Our system assembly area provides for in-house fabrication of your equipment. That translates into AWS having full control of your system’s quality through every step of the process. Our flex space allows us to build everything from small single unit softeners and filters to large volume high purity systems.

Prior to delivery, we carefully check the equipment with a series of quality and functionality tests to ensure that it is operating at optimum performance.

Whether it be full integration, alarms, or alerts, a PLC (programmable logic controller) is the answer. Our control panels are built in our panel assembly room to meet your exact specifications. Programs are written based on the combined efforts of the customer’s request along with our water treatment/industry expertise. Go To Page

AWS recognizes the need to be good water stewards as we have been given a very finite amount of this wonderful resource. As such, we have dedicated our resources and expertise to recycle 50% of our water used in our various processes. We developed a system to capture, purify, and re-use thousands of gallons of water each and every day. In fact, this system was so successful two additional phases were implemented to further enhanced our efforts.